High Speed Computerized Knitting Machine with Jacquard for Socks Hat and Scarf Sweater Collar School Uniform Jersey Cuff Fly Shoe Upper Cardigan

Basic Info.

| Model NO. | HT23003KM |

| Needle Style | Bearded Needle/Spring Needle |

| Needle Bar Style | Flatbed Knitting Machine |

| Computerized | Computerized |

| Certification | ISO9001: 2000 |

| Condition | New |

| After-sales Service | Online Service and Video Technical Support |

| Speed | 1.6m/S |

| Knitting Width | 36-120 Inch |

| Guage | 14G |

| Weight | 1000 Kg |

| Key Selling Points | High-Accuracy |

| Drive System | Synchronous Belt Drive ,AC Servo System |

| Marketing Type | Ordinary Product |

| Keywords | Fully Automatic Knitting Machine |

| Frequency Power | 50Hz/60Hz 1.5kVA |

| Knitting Machine Type | Plain Knitting Machine |

| Processing Capacity | 800 Units/Month |

| Dimension(L*W*H) | 2.8*1*1.8 Meter |

| Machinery Test Report | Machinery Test Report |

| Core Components | Circuit Board, Motor |

| Applicable Industries | Manufacturing Plant, Home Use, Retail |

| Transport Package | Wooden Box |

| Specification | 16G AC 220V/380VA |

| Trademark | HARTAUN |

| Origin | Jiangsu, China |

| HS Code | 8447202000 |

| Production Capacity | 800 Pieces/Year |

Product Description

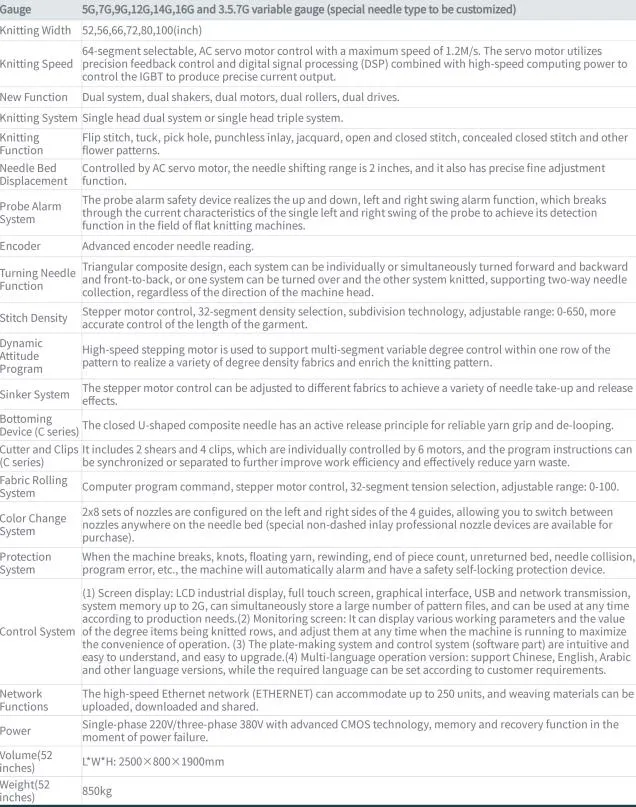

| High Speed Computerized Knitting Machine with Jacquard for Socks Hat and Scarf Sweater Collar School Uniform Jersey Cuff Fly Shoe Upper Cardigan |

Divided structure ,steel sheet made from import high quality steel precisely punched and fine polished to reduce the resistance with needles and increase the longevity.

Carriage:

The journey of the carriage can be automatically adjusted as per the width of the knitting fabric.The adjustment can be done swiftly and the positioning is precise,which avoids the useless movement and greatly elevates the productivity of the machine.

Q1.Can you provide OEM service?we can provide OEM service. It will depend on your requests,your logo will be customized on our products.Q2.How many days about delivery time?15-20 days after TT deposit.Q3.What is the packing? General machines are with vacuum packing. Particular machine are packing with vacuum and wooden case. Container loads as per the machine size.Q4. What information may contain in my inquiry? Your request your machine's embroidery area /needle number /head number/head interval/other function need.Q5. Do you test all your goods before delivery?Yes, we have 100% test before deliveryQ6.How to insatll and use the embroidery machine? We have the English teaching manual and videos;The videos about every step of machine Disassembly, assembly, operation.Q7: How do you make our business long-term and good relationship?1. We keep good quality and competitive price to ensure our customers benefit ;2. We respect every customer as our friend and we sincerely do business and make friends with them.

Daily maintenance methods(1) use a brush to clean the rotating shuttle, shuttle shell and shuttle core of the hooking mechanism. Do not use sharp and hard tools to remove sundries and threads.

(2) remove sundries and thread ends at the height of wire rod, wire channel and felt;

(3) four pairs of guide rail (type 615) in front and rear of Y-axis feeding mechanism are on the same plane;

(4) two X-axis feeding mechanism guide rails are on the same plane;

(5) wire clip mechanism, wire clip, rotating wheel, wire pick, spring and wire channel are often cleaned up;

(6) cleaning sundries on the surface of work surface;

(7) the surface of the computer and the exhaust fan are often rubbed and the back cover is opened;

(8) power box, drive box surface and ventilation are often as above.