Hot Sale 52 Inch Single System Semiautomatic Pullover Collar Cuff Knitting Machine

Basic Info.

| Needle Style | Bearded Needle/Spring Needle |

| Needle Bar Style | Flatbed Knitting Machine |

| Computerized | Computerized |

| Certification | CE, ISO9001: 2000 |

| Condition | New |

| After-sales Service | Online Service |

| Speed | 1.6m/S |

| Control System | Hengqiang/Raynen System |

| Motor | Servo Motor |

| Knitting Width | 36/52/72/80 Inches |

| Certificate | CE ISO |

| Guage | 3G-18g |

| Application | Fabric Knitting |

| Product Name | Computerized Flat Knitting Machine |

| Transport Package | Wooden Box |

| Trademark | BENOY |

| Origin | China |

| HS Code | 844720 |

| Production Capacity | 2000 Set/Month |

Product Description

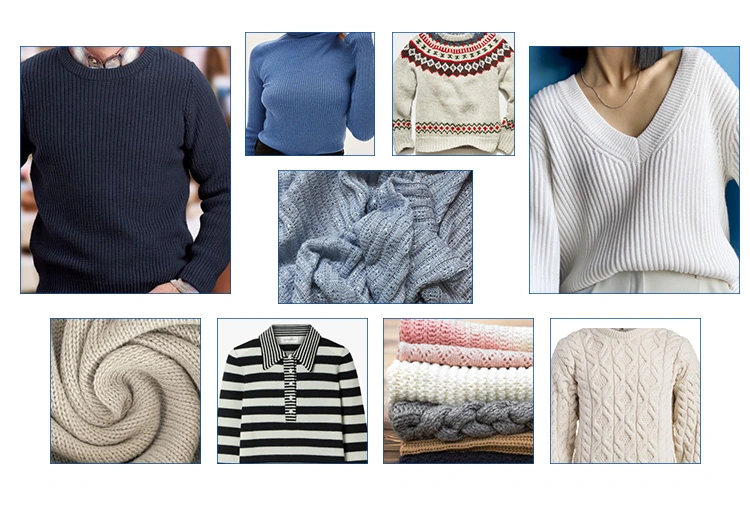

Single Carriage with Double system, this computerized flat knitting machine are used digital technology to achieve the patterns of knit, transfer, tuck, pointel, intarsia, jacquard ,apparent shape, hidden shape, and other regular or irregular patterns knitting functions, can knit basic single or double jersey plain fabric, irregular multi-color jacquard, intarsia, cable and pointel structure patterns , which suitable to knit by yarns of pure silk, mixed silk, synthetic, wool,acrylic, mixed fiber material etc.

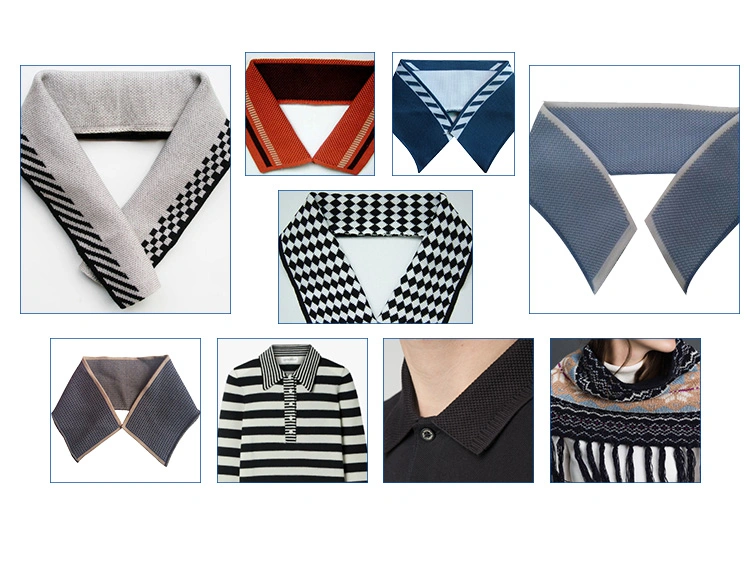

Knitted for shaping fabric and accessories of sweater, collar, cardigan, rib, cuff, scarf, pocket, pullover, jersey, Blanket, Carpet etc.

Advantages

- The fast cornering of carriage. Superior servo drive saaembly makes the fast cornering of carriage came true, improved the efficiency of knitting more than 20%.

- Well-designed angle of needle bed tooth mouth to ensure rapid antonomous falling of fabrics.

- Improved sinker makes needle insertion more stable.

- Needle bed displacement system features precise positioning and rapid response, racking within 2 inch.

- Needle plates are replaceable and stable and with high hardness by using insert model, to make it longer service life.

Parameters:

| Series | High Speed Collar Knitting Machine |

| Gauge | 12G 14G 16G |

| Knitting Width | 36" 52" 72" 80" 100" |

| Knitting System | Single carriage single system / 1+1 two head double system / 2+2 two head four system |

| Knitting Speed | Max 1.4m/s, 32 section adjustable |

| Knitting Function | Transfer, tuck, intarsia, jacquard, hide, or apparent shaping and other regular or irregular patterns |

| Transfer cam | The transfer cam is compose designed, single or double cam system all can transfer which will achieve to high production efficiency knit. |

| Racking | Motor drive, the maximum racking within 2 inches |

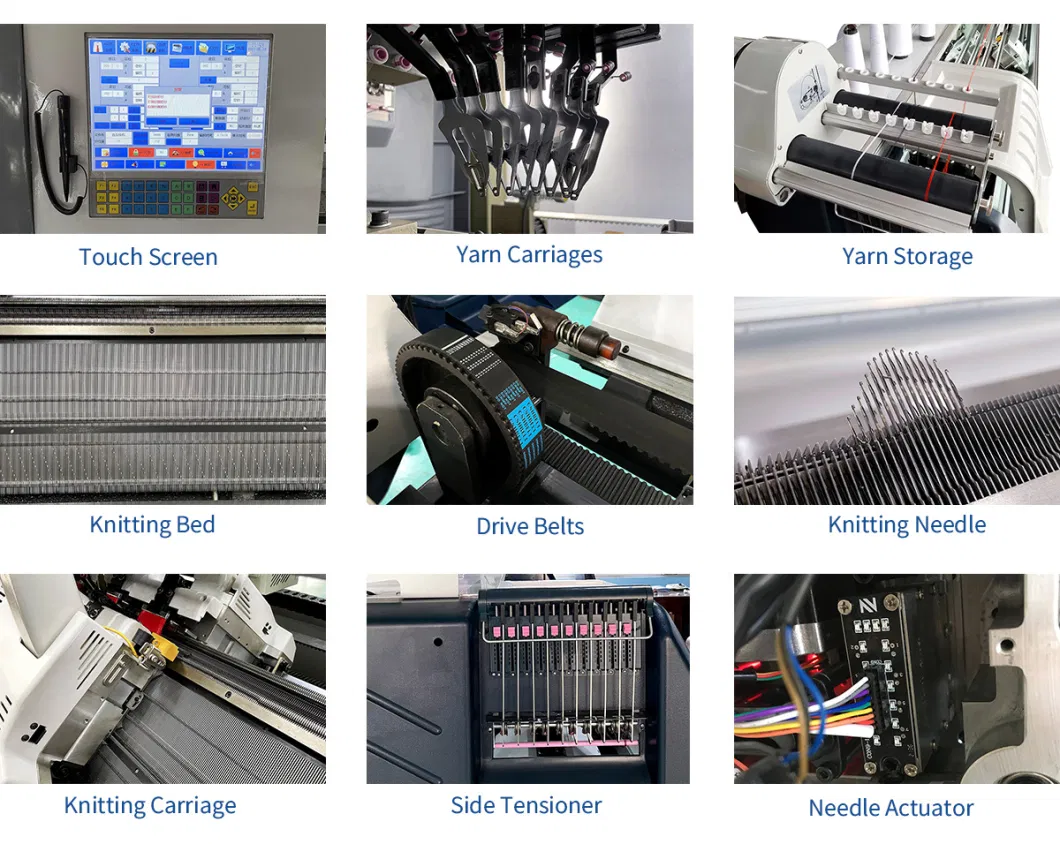

| Needle actuator | 8 section electronic needle actuator |

| Sinker | Driven by stepping motor, latest cross-sinker system design, Can be adjusted for different fabrics |

| Roller device | High-order Rollar, 32 section automatic control, subsection adjustable |

| Stitch density | Controlled by 32 section electricity, density adjustment driven by stepping motor, the adjustable range:0-650 |

| Yarn forward device | Yarn feeder and yarn storage device(optional),accurate control of yarn tension, to ensure the quality of the overall quality of the fabric |

| Yarn feeder | 2*8 yarn carriers are arranged on the left and right sides of the 4 double side guide rails. |

| Transmission system | Belt drive, AC servo motor control. |

| Data input | Input and output patterns via USB, PC and Internet |

| Protection system | Automatic stopping device if yarn broken, yarn knot, batching, striking, completion, overload, designated starting and stopping, program error |

| Safety device | The whole machine cover to reduce noise and dust, the protecting cover is equipped with stopping sensor, emergency stopping and power off device |

| Control system | Hengqiang/Raynen system |

| The screen adopts LCD touch screen display, graphical interface, can store a large number of pattern files, and can be called at any time according to production needs. | |

| Through the screen checking page, you can view the working status and actual position of the cam; and adjust it at any time while the machine is running, which is most convenient for operation. | |

| The control system (software part) and the pattern-making system are easily upgraded and are free of charge. | |

| Multi-language version switching (Set up according to customer requirements) | |

| Power | Voltage: Single phase AC 220-380V, Power:1.5KW CMOS technology, has the memory function at power-off moment |

Benoy flat knitting machines are mainly suitable for sweaters, shoe upper, jacquard collar, blankets, carpets, scarf, cuffs, hats, etc.

Dongguan Benoy Intelligent Technology Co., Ltd. was established in 2003. It is a knitting solution manufacturer in high-speed computerized flat knitting machines and flying knitting upper knitting machines, integrating the design, development, production and sales . The factory is located in Dalang Town, Dongguan City, Guangdong Province, and has a sales office in Songshan Lake High-tech Zone. Our factory has passed ISO9001 quality management system certification, and all flat knitting machines are confirm to CE certification. We also got many appearance patents and technical patents. In the highly technologically intensive knitting machinery manufacturing filed, we have won the trust of widely customers with our unique technological innovation, good market reputation, and complete after-sales service system. We will be your reliable business partner.

CertificationsPackaging & ShippingContact Us